Carbon Footprint

Life cycle analyses (LCA) show that the Pure-Pak® carton significantly outperforms other packaging, particularly in terms of greenhouse gas emissions.

What is environmental footprinting?

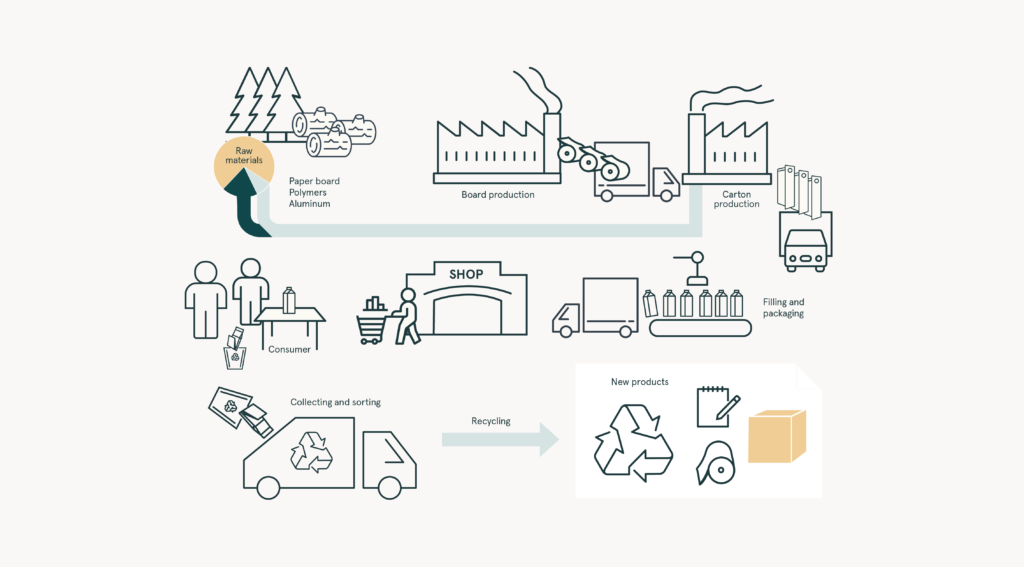

Environmental Footprinting is a way of quantifying the impact a certain product has on the environment. It looks at the whole value chain from the sourcing of raw materials, via our own and suppliers’ production processes, to our customers, retail and consumers and finally end-of-life. In each step, there is an environmental impact.

Multiple life-cycle assessments (LCA) prove that beverage cartons perform better than plastic bottles in a number of environmental impact categories.

In 2023, Anthesis Ltd conducted a life-cycle assessment for Elopak’s customer Postevand, filling water in cartons in Denmark. The study shows that over its full lifecycle, a Pure-Pak® carton performs better than a rPET bottle (with 100% recycled PET) in 6 of 8 impact categories, including climate impact. Read the summary below, or see the full report on Postevand’s website.

In 2021, an LCA was carried out by Anthesis Ltd, demonstrating that over its full life cycle, the average Pure-Pak® carton presents a lower carbon footprint than a typical HDPE or PET bottle for milk and juice in the North American market.

In 2019, a Life Cycle Assesment (LCA) was done by the Institute for Energy and Environmental Research Heidelberg (IFEU) in Germany. Results prove that beverage cartons are ecologically advantageous compared to single-use PET bottles and reusable glass bottles for packaging of milk and juice in the German market. Read more here.

In Elopak we also have an internal cradle-to-gate calculation tool called “DEEP – Dynamic Elopak Environmental Performance”. It considers all emissions connected to the production of all raw materials. In addition, DEEP covers Elopak’s own operations including final conversion and all transportation up to the delivery to customers’ gate. By using DEEP it is possible to find the total cradle to gate emission for a specific Elopak carton configuration.

Our carton is already a low emission alternative. However, Elopak continuously works to further lower the footprint through weight, waste and plastic reduction, renewable materials, production and transport efficiencies.