Solving mysteries with microbiology

Anette always knew she wanted to work in research and holds a PhD in Food Safety from the Norwegian School of Veterinary Science and a Bachelor of Science in Biotechnology from Griffith University in Brisbane, Australia.

Anette always knew she wanted to work in research and holds a PhD in Food Safety from the Norwegian School of Veterinary Science and a Bachelor of Science in Biotechnology from Griffith University in Brisbane, Australia.

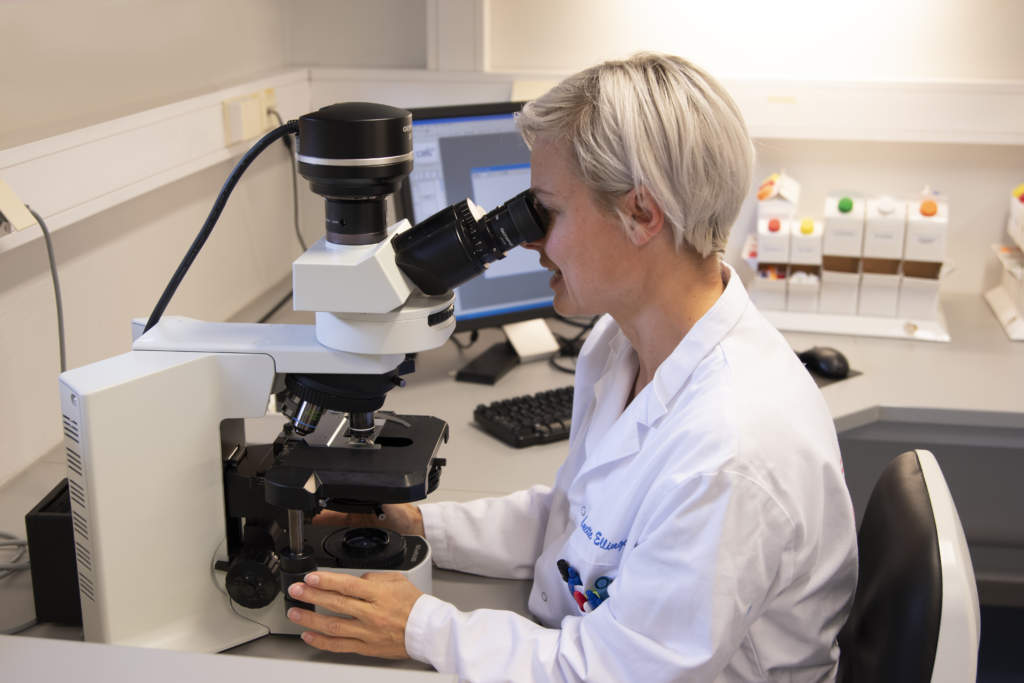

Anette Bauer Ellingsen, Senior Food Microbiologist, joined Elopak in May 2014. “In my 7th year at Elopak, I am still continuously learning. We hold so much know-how about the product, the filling systems and our Pure-Pak® carton at Elopak with many different areas of expertise under one roof. And because the system and the humble carton is extremely complex in its many forms and functionalities, my work is always interesting.”

Anette and the Food Science Support team she is part of, focus their work in Elopak’s microbiology lab, where identification of microbes and the validation of sterilization efficiency is the main focus. “Getting to know your team is essential to cooperation, and cooperation is vital to success,” Anette explains.

“The Food Science support team consists of a group of scientists and experts with vital know-how of food science and hygiene as well as technical training, and with knowledge of different product’s lifespan.”

It is vital that we are involved and can give input from the start, in any new product development whether materials, configurations or filling machines. We are responsible for the final validation of the functionality and integrity of the carton throughout the supply chain and the safety of our customers’ content.

The microbe detectives

“In a normal year, we would provide guidance and support for customers, off and on-site. Firstly, if a customer has an issue that cannot be resolved on-site, they will send us to assist or send samples to test here in the microbiology lab. We will perform tests on the product to see what microbes exist but also do tests on the carton itself. At the customer’s site we will look at the filling machine and do hygienic tests and look for problem microbes in critical areas. We are looking for the root cause, and it is often like solving a mystery, and we are the detectives. Of course, recent times have been very different for everyone, and we have had to adapt and support customers from afar.”

The role of the team extends across the supply chain, from converter hygiene in Elopak’s plants to how the filled carton performs together with secondary packaging and on the pallet during shipping. One key and final part in many development projects is the sterile test with transport simulation, where a relatively large number of cartons are filled, packed and meticulously placed on over 34 pallets. They are then checked for microbial contamination after a final 21 days of incubation.

“This is not just a product; it is a process and a system, and we have to evaluate the whole system to ensure optimum hygiene and quality. It is the expertise and breadth of competence of the whole team that enables us to have a good understanding of the complexity of the system.”

Keeping the wheels turning in lockdown

“Innovation does not stop because of a global pandemic,” adds Anette. “We adapted quickly with strict measures so that the lab remained fully operational to keep the wheels of progress turning. Through great teamwork and communication, we have been able to solve many challenges remotely. However, we also realize how much you miss with a home office. You miss out on interaction with team members and other colleagues where you absorb the knowledge and enthusiasm that leads to new ideas and innovation.”